India’s formidable freight sector, a linchpin of its economic growth, is on the cusp of a transformative shift with the rapid expansion of battery swapping technology into the heavy-duty electric truck segment. Traditionally confined to two and three-wheelers, this innovative energy delivery model is now being championed by key players like Pune-based e-truck manufacturer Blue Energy Motors and Murugappa Group’s Montra Electric, both of whom are introducing 55-tonne electric trucks designed for seamless battery interchangeability. This strategic pivot addresses critical barriers to large-scale commercial EV adoption, namely the prohibitive upfront cost of electric vehicles and the operational downtime associated with conventional charging methods.

The electrification of heavy-duty transport is paramount for India’s decarbonization goals. Despite comprising only about 3% of the total vehicle fleet, trucks contribute a disproportionate 40% of the transport sector’s total polluting emissions. The environmental dividend from transitioning these leviathans to electric power is thus immense, making it a high-impact area for green mobility initiatives. However, the commercial viability of electric trucks has long been hampered by significant price disparities; heavy electric trucks exceeding 12 tonnes typically cost between ₹1 crore and ₹1.5 crore, starkly contrasting with diesel counterparts priced at ₹25-50 lakh. Moreover, the extensive charging times required for large battery packs presented a significant operational hurdle for logistics companies dependent on high asset utilization.

Battery swapping emerges as a potent solution, effectively decoupling the battery from the vehicle’s purchase price. Since the battery often accounts for nearly half the cost of an electric vehicle, its exclusion from the initial sale dramatically reduces the upfront capital expenditure for fleet operators. This "energy-as-a-service" model, where the battery is leased or subscribed to, transforms energy from a fixed asset into a flexible operational expense. As Montra Electric’s Chief Business Officer, P.V. Satyanarayana, elucidates, this strategy is fundamental to achieving price parity between electric and internal combustion engine (ICE) trucks and significantly improving the total cost of ownership (TCO). By minimizing charging times, fleet managers can maximize the operational hours of their vehicles, a practice known as "sweating the asset," thereby enhancing profitability and accelerating the return on investment. The ability to swap a depleted battery for a fully charged one in mere minutes – often less than half the time it takes to refuel a diesel truck – eradicates the lengthy downtimes associated with traditional charging, which can range from 45 to 90 minutes for heavy-duty vehicles.

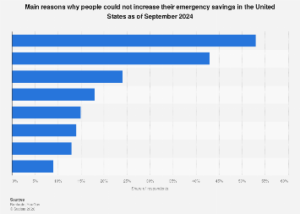

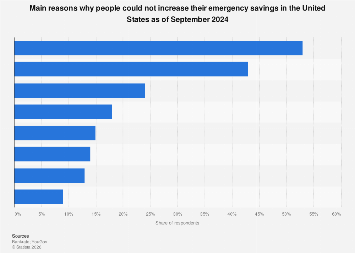

The Indian EV battery-swapping industry is experiencing robust growth, projected to expand from an estimated $10.2 million in 2022 to $61.57 million by 2030, exhibiting a compound annual growth rate (CAGR) of 25.2%. This growth trajectory outpaces the broader Indian EV market, which is expected to double in value from approximately $55 billion in 2025 to ₹110 billion by 2029, with a CAGR of 19.44%. Such rapid expansion underscores the increasing recognition of battery swapping’s economic and operational advantages, particularly as technological advancements enhance the efficiency of battery charging and swapping processes.

Several key players are spearheading the commercial rollout and infrastructure development. Energy in Motion (EIM), a battery-swapping company affiliated with renewable energy firm Ravindra Energy Ltd., is actively deploying swappable-battery e-trucks in collaboration with China’s Foton (Beiqi Foton Motor Co. Ltd.). EIM has strategically established battery swapping stations at critical logistics hubs, including Mumbai’s Jawaharlal Nehru Port Trust (JNPT) and Sonepat, with plans to launch eight more stations at other ports and within the National Capital Region by March 2026. Narendra Murkumbi, Managing Director and CEO of EIM, highlights the dual benefit of swapping in India: "It is not just a technical solution for fast charging, it is also a financial solution. It allows truck operators to invest only in the vehicle, while the batteries are centrally owned and deployed by a network operator like us." This centralized ownership model for batteries mitigates the high capital expenditure for individual truck operators and ensures optimal battery health and lifecycle management.

Similarly, Blue Energy Motors, manufacturing its 55-ton e-trucks near Pune, is integrating battery swapping into its energy-as-a-service ecosystem. Anand Mimani, CEO of the company’s EV and new-energy business, emphasizes that this integrated approach, where the charging network and batteries are centrally owned, allows for the sale of trucks without batteries, slashing the acquisition cost for transporters by almost half and significantly narrowing the price gap with diesel trucks. The operational efficiency gains are substantial; while a diesel truck takes approximately 10 minutes to refuel, a swappable battery e-truck can be back on the road in 50% of that time. These electric heavy-duty vehicles are versatile, capable of handling diverse cargo, from fast-moving consumer goods and express cargo to steel, cement, and chemicals, across a variety of sectors.

The supporting infrastructure is also scaling up. India had approximately 3,500 battery swapping stations managing around 350,000 batteries in early 2025. While public EV charging stations are more numerous, totaling about 29,000 across India as of August 2025, the strategic placement and rapid service of swapping stations are critical for high-utilization commercial fleets. The government’s policy support is proving instrumental, with the PM E-Drive scheme incentivizing both e-trucks and battery swapping stations, allocating ₹500 crore and ₹2,000 crore respectively. Crucially, the scheme covers 80% of the upstream costs for public battery swapping stations, including grid connection expenses, thereby reducing the significant capital outlay for infrastructure developers. This policy push, as noted by Deepali Thakur, Senior Technical Manager at Smart Freight Centre India, is "emerging as a critical first driver of the electric truck transition," complemented by state-level EV policies offering capital subsidies, tax exemptions, and operational incentives.

Despite the compelling advantages, battery swapping is best suited for specific operational profiles. Domain experts, including Thakur, suggest it excels in short, fixed, high-utilization routes where minimal downtime is paramount. For longer-haul operations, direct-current fast-charging remains essential. This distinction arises from the typical design of swappable batteries, which are often modular and smaller (around 1 to 1.5 kWh, weighing 10-12 kg) to facilitate easy handling and interchangeability. While suitable for light EVs and heavy-duty trucks requiring intense daily use, these smaller units might necessitate more frequent swaps for extended journeys compared to vehicles with larger, fixed battery packs. The core challenge for battery swapping infrastructure remains the substantial capital expenditure required for acquiring batteries and constructing high-tech swapping stations. However, declining battery prices—a 75% reduction since 2015, according to the International Energy Agency’s Global EV Outlook 2025—and advancements in charging speeds are making the model increasingly economically viable. Operators can now manage their fleets with fewer spare batteries, as demonstrated by Montra Electric’s plan for swap stations to service 150 vehicles daily with just 6-7 rotating batteries.

Looking ahead, the convergence of technological innovation, strategic infrastructure development, and supportive government policies positions battery swapping as a cornerstone of India’s electric truck revolution. While challenges such as standardization across different truck manufacturers and the initial investment in swapping infrastructure persist, the undeniable benefits of reduced TCO, enhanced operational efficiency, and significant decarbonization potential make this model an attractive proposition. As India strives to meet its ambitious climate goals and modernize its logistics sector, battery swapping is not just an alternative; it is rapidly becoming an indispensable strategy for powering the future of heavy freight.