India’s steel industry has achieved a significant milestone, transitioning into a net exporter of finished steel during the April-December 2025 period. This shift, a stark reversal from years of battling cheap inbound shipments, marks a critical juncture for the nation’s manufacturing landscape. However, analysis reveals that this strategic pivot is less a testament to burgeoning domestic demand and more a direct consequence of robust governmental intervention aimed at fortifying local producers against global competition. The implications for India’s economic resilience, its trade relationships, and the future trajectory of its heavy industry are profound, yet complex, as global market dynamics continue to evolve.

The Policy Bulwark: Shielding Domestic Steel

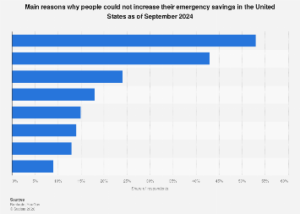

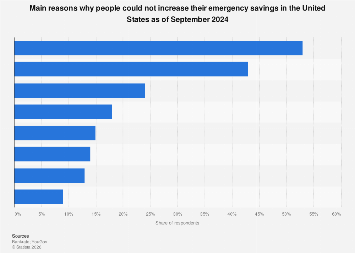

The turnaround in India’s steel trade balance is predominantly a story of policy effectiveness. A comprehensive suite of measures, including safeguard duties and stringent quality control orders, has significantly curtailed imports. Data from the Ministry of Steel for April-December 2025 illustrates this dramatic shift: finished steel exports surged by 33% year-on-year to 4.79 million tonnes (mt), up from 3.60 mt in the corresponding period of the previous year. Concurrently, imports plummeted by 37%, registering 4.65 mt compared to 7.42 mt a year prior. This dramatic narrowing of the trade gap has allowed India to emerge as a net exporter, a position it only marginally held as a net importer by 0.01 mt as recently as April-November 2025.

Industry experts, such as Dhruv Goel, CEO of commodities market intelligence firm BigMint, underscore this policy-driven narrative. "While the current data shows a near balance between imports and exports, this is more a result of restricted imports than a surge in demand-led exports, and the sustainability of this balance remains uncertain," Goel observed. The decline in imports was not solely due to duties; several Vietnamese mills, once key suppliers to Indian traders, lost mandatory Indian quality certifications, further tightening the flow of foreign steel. This dual approach of imposing tariffs and enforcing quality standards created a formidable barrier to entry for international competitors.

The government’s commitment to protecting its steel sector was formalized with the imposition of a staggered safeguard duty on December 30, 2025. This tariff began at 12%, set to decrease to 11.5% in the second year and 11% in the third. Crucially, this duty applies only to imports priced below specified thresholds, a targeted measure to prevent dumping. The levy encompasses a range of vital flat steel products, including hot-rolled coils and plates, cold-rolled coils, metallic-coated steel, and colour-coated steel—materials indispensable across construction, automotive, appliance manufacturing, and infrastructure development. This long-term measure replaced a temporary 12% safeguard duty that had been in place for 200 days since April 2025, signaling a sustained policy stance. The expected outcome, according to Goel, is that "steel imports are expected to remain in the range of 4–5 million tonnes annually."

Domestic Pressures and Export Imperatives

While import curbs have provided a crucial breathing room, the domestic market presented its own set of challenges, inadvertently propelling the export drive. Despite the protective tariffs, domestic steel prices remained subdued, largely due to a significant oversupply combined with a softer-than-anticipated demand. This imbalance created an urgent need for Indian producers to offload surplus inventory into international markets.

Ministry data highlights this disequilibrium: steel consumption grew by a modest 6.8% during April-December 2025, a significant deceleration from the 11% growth recorded a year earlier. This slowdown in demand can be attributed to a confluence of factors, including global economic headwinds impacting manufacturing sectors, potentially higher domestic interest rates dampening investment, and a slower pace of execution in some large-scale infrastructure projects. In stark contrast, domestic steel production surged by 10% during the same period, accelerating from 4% growth in April-December 2024. This widening gap between production and consumption created a glut, exerting downward pressure on prices.

The price trajectory of Hot-Rolled Coil (HRC), a benchmark product, illustrates this pressure. In April 2025, HRC prices hovered around ₹52,000 per tonne, broadly competitive with Japanese imports and even cheaper than Chinese steel. However, by November, prices had slid to a 10-month low of approximately ₹47,100 per tonne. At this point, Indian HRC was significantly more economical than imported Chinese and Japanese steel, creating a compelling incentive for producers to seek export avenues, even amid a generally weak global demand environment. This cost advantage, combined with the surplus capacity, effectively transformed Indian steelmakers into opportunistic exporters.

Navigating Global Markets: Opportunities and Obstacles

The global steel market is a complex tapestry of demand, supply, and protectionist measures. India’s export strategy has naturally gravitated towards markets where its products can find a foothold. Europe emerged as the largest destination for Indian steel, accounting for over 40% of shipments during April-November 2025. Specifically, Italy, Spain, and Belgium together absorbed 1.71 mt of India’s 4.18 mt steel exports during this period. This preference for European markets can be attributed to various factors, including specific regional demand patterns, established trade relationships, and the quality specifications of Indian steel that align with European requirements.

Intriguingly, India also saw an increase in shipments to Vietnam. This development reflects the intricate nature of global steel trade flows, as Vietnam itself had imposed duties on Chinese steel, creating a vacuum that Indian producers were able to fill. This demonstrates how protectionist measures in one region can create ripple effects and open new markets for other exporting nations.

Despite the recent price hikes announced by Indian steelmakers in January 2026, following the three-year duty implementation (HRC and Cold-Rolled Coil prices rose by 2-4%, and rebar prices by 3-6%), domestic prices continue to trade at a discount to imports. On January 13, 2026, benchmark HRC prices stood at ₹51,500 per tonne, still notably below the landed cost of ₹56,125 per tonne for Chinese steel. This sustained price differential reinforces the economic rationale for Indian producers to prioritize export opportunities when domestic demand falters.

The Road Ahead: Sustainability and Global Challenges

The long-term sustainability of India’s net exporter status, however, remains subject to significant global market dynamics and evolving trade policies. Dhruv Goel warns that India’s export outlook is "heavily tied to Europe, and any tightening of quotas or carbon-related rules there could quickly weigh on volumes." This caution highlights critical challenges that Indian steelmakers must confront.

Foremost among these is the looming specter of carbon-related trade barriers, particularly the European Union’s Carbon Border Adjustment Mechanism (CBAM). Designed to prevent carbon leakage and ensure that European industries are not disadvantaged by stricter environmental regulations, CBAM will impose a levy on carbon-intensive imports, including steel, based on their embedded emissions. For Indian steel, which largely relies on coal-fired blast furnaces, compliance with CBAM could significantly increase export costs, potentially eroding its price competitiveness in a crucial market like Europe. The imperative for Indian steel producers to accelerate decarbonization efforts, invest in green steel technologies, and adopt more sustainable production methods is no longer just an environmental concern but a critical trade requirement.

Beyond carbon tariffs, the potential for other protectionist measures, such as stricter import quotas or anti-dumping investigations in destination markets, could further complicate India’s export ambitions. Over the medium term, Goel emphasizes, "export growth will depend on India’s ability to improve cost competitiveness and address carbon-related barriers in global markets." This necessitates not only technological upgrades but also strategic investments in raw material security, energy efficiency, and logistics infrastructure to reduce overall production costs.

Economic Implications and Strategic Imperatives

The shift to a net steel exporter position carries significant economic implications for India. It signals a move towards greater self-reliance in a core industrial sector, potentially safeguarding thousands of jobs and ensuring the viability of domestic steel manufacturers. By reducing reliance on imports, India also strengthens its balance of payments and mitigates the impact of global price volatility on its internal economy. The government’s policy framework, therefore, serves as a strategic tool to bolster industrial stability and foster growth within the "Make in India" initiative.

However, policymakers face a delicate balancing act. While protectionist measures shield domestic producers, they can also increase input costs for downstream industries like automotive and construction, potentially impacting their competitiveness. The long-term vision must therefore extend beyond merely restricting imports to fostering an internationally competitive and environmentally sustainable steel industry. This involves not only continued investment in capacity expansion and technological modernization but also a proactive engagement with global climate frameworks and a commitment to green manufacturing processes.

In conclusion, India’s emergence as a net finished steel exporter in 2025 represents a significant policy triumph, demonstrating the government’s resolve to protect and promote its domestic industry. Yet, this success is intertwined with the challenges of oversupply and subdued domestic demand, which have pushed producers towards international markets. As India looks ahead, its ability to sustain this export momentum will hinge on navigating an increasingly complex global trade landscape, particularly addressing the rising importance of carbon compliance and enhancing overall cost competitiveness. The journey from import dependence to export prominence is far from over, with the next phase demanding strategic foresight and significant investment in a greener, more resilient steel future.