India is embarking on an ambitious journey to transform its electronics manufacturing landscape, moving beyond mere assembly to establish a robust, indigenous component ecosystem. This strategic pivot, underscored by significant government incentives and substantial private sector investments, aims to diminish the nation’s reliance on global supply chains, particularly from China, for critical components like mobile phone enclosures. The latest wave of approvals under the Electronics Components Manufacturing Scheme (ECMS) highlights this resolve, with a staggering ₹41,863 crore in new investments cleared across 22 projects, bringing the cumulative scheme investments to ₹54,567 crore across 46 projects. At the forefront of this industrial resurgence are powerhouses such as Tata Electronics, the Indian subsidiary of Taiwanese giant Foxconn (Yuzhan Technology), and the diversified Motherson Group, collectively committing ₹27,166 crore, signaling a profound shift in the country’s manufacturing capabilities.

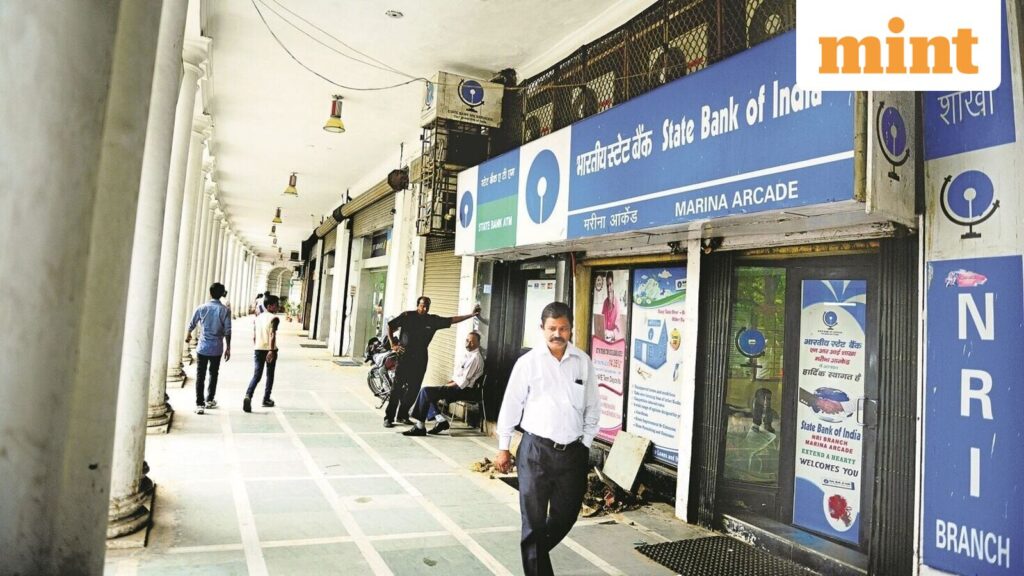

This concerted effort is a cornerstone of India’s broader "Make in India" and "Atmanirbhar Bharat" (self-reliant India) initiatives, designed to foster domestic manufacturing and reduce import dependency. The ECMS, alongside the Production Linked Incentive (PLI) scheme for mobile phones and other electronics, provides crucial financial support and policy stability, attracting both domestic and international investors. These schemes offer incentives tied to incremental sales and manufacturing, creating a favorable environment for high-volume, high-value production. The focus on mobile phone enclosures is particularly strategic. These metal frames or casings are the foundational structure upon which all other smartphone components are mounted, accounting for over 10% of a mobile phone’s bill of materials. Historically, India has been almost entirely dependent on imports, primarily from China, for these high-precision components. Localizing this crucial segment not only adds significant value to the domestic economy but also enhances supply chain resilience against geopolitical disruptions and trade volatilities.

The commitment from industry leaders underscores the viability and potential of India as a global manufacturing hub. Tata Electronics, a division of one of India’s largest conglomerates, is making a formidable entry into this high-precision domain, reflecting a strategic intent to build a vertically integrated electronics manufacturing presence within the country. While specific investment figures for each player were not disclosed, Tata’s participation signals a long-term vision for deep engagement in India’s electronics future, potentially spanning various product categories. For Foxconn, the world’s largest contract electronics manufacturer and a key supplier to global tech giants like Apple, its Indian arm Yuzhan Technology’s move into component manufacturing is particularly symbolic. Dinkar Malladi, resident director and vice-president at Yuzhan Technology India, emphasized this significance, stating that it marks the first time a Foxconn Group entity has diversified its component manufacturing operations outside of China. This strategic shift reflects a broader global trend among multinational corporations to de-risk supply chains by adopting a "China+1" strategy, exploring alternative manufacturing bases to mitigate concentration risks. Foxconn’s plans include establishing a "lights-out factory" with Industry 4.0 automation, focusing on local procurement and bringing its extensive ecosystem to India, promising advanced manufacturing capabilities and technology transfer.

Equally significant is the entry of the Motherson Group, a major player in the automotive components sector, into electronics manufacturing. Their wholly-owned subsidiary, Motherson Electronic Components, established in March 2023, is poised to leverage the ECMS framework to establish mobile enclosure manufacturing facilities. Som Dutt Mehta, chief information officer and executive vice-president at Motherson Electronic Components, credited the ECMS scheme as a pivotal factor in their diversification into electronics, highlighting its role in boosting employment and increasing India’s market share in the global components ecosystem. The collective investment from these three industrial titans, amounting to over ₹27,000 crore, represents a substantial portion of the total approved investments, demonstrating strong industry confidence in India’s manufacturing potential and policy support.

Beyond mobile enclosures, the government’s approvals on this particular day also marked a broader expansion into other critical electronics components. Dixon Technologies received approval for a ₹550 crore investment in a local assembly line for camera modules, a crucial element in modern smartphones and other imaging devices. Samsung, a global leader in display technology, is investing ₹524 crore through its local unit to assemble OLED displays for smartphones and televisions. These investments are vital, as camera modules and high-quality displays represent significant portions of a device’s bill of materials and are key differentiators in consumer electronics. Additionally, nine new projects for Printed Circuit Boards (PCBs) were approved, with a cumulative investment of ₹7,377 crore. PCBs are the backbone of virtually all electronic devices, and localizing their production is fundamental to building a comprehensive electronics manufacturing ecosystem. These diverse investments signify a holistic approach, aiming to create an integrated supply chain that reduces reliance on imports across multiple component categories.

The economic impact of these initiatives is multifaceted and substantial. Job creation stands out as a direct benefit: Foxconn’s project alone is expected to generate 16,210 new jobs, Tata’s plant will add 1,500 positions, and Motherson’s entry into electronics is projected to employ 5,741 individuals. These figures represent direct employment, with significant multiplier effects anticipated in ancillary industries, logistics, and services. The influx of investment and the establishment of advanced manufacturing facilities are also expected to drive skill development and technological upgrades within the Indian workforce, preparing it for the demands of Industry 4.0. Furthermore, S. Krishnan, secretary at the Ministry of Electronics and IT (MeitY), emphasized the strategic decision to approve capital-intensive segments like mobile phone enclosures as a means to boost export opportunities and enhance the electronics industry’s contribution to India’s gross domestic product. He stressed that any production under the ECMS must be export-competitive to truly realize the benefits of import substitution and global market penetration. This focus on export capability positions India not just as a domestic market for electronics, but as a potential global manufacturing and supply hub, competing with established players in East Asia.

The shift towards localizing high-precision components like mobile enclosures, displays, and camera modules is instrumental in elevating India’s position in the global electronics value chain. For years, India has been a significant market for mobile phones and a growing hub for final assembly. However, moving up the value chain into complex component manufacturing represents a qualitative leap. This transition not only enhances the domestic manufacturing ecosystem but also strengthens India’s geopolitical standing by reducing strategic vulnerabilities inherent in concentrated supply chains. As global corporations increasingly seek diversified manufacturing bases, India’s large domestic market, growing pool of skilled labor, and supportive policy environment make it an attractive alternative. While challenges such as ensuring consistent infrastructure, fostering a deeper R&D ecosystem, and navigating global trade dynamics remain, the momentum generated by these investments and policy frameworks positions India on a promising trajectory to become a formidable force in the global electronics manufacturing arena, ushering in an era of self-reliance and export leadership.