The competitive landscape of India’s automotive sector is undergoing a profound transformation, as indigenous car manufacturers like Tata Motors and Mahindra & Mahindra are dramatically shortening their product development cycles, mirroring the rapid-fire innovation playbook historically associated with Chinese original equipment manufacturers (OEMs). This strategic pivot is not merely about speed; it reflects a sophisticated evolution in engineering, supply chain management, and market responsiveness, allowing domestic players to fiercely contest market share against long-established European, Japanese, and Korean automotive giants. Evidence of this growing prowess is clear: Mahindra & Mahindra, for instance, ascended to the second-highest position in annual sales in 2025, a significant milestone that saw it overtake Hyundai Motor India Ltd for the first time in over a decade, according to retail registration data.

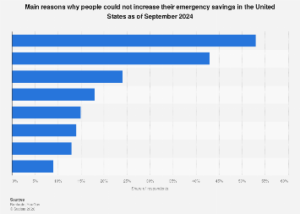

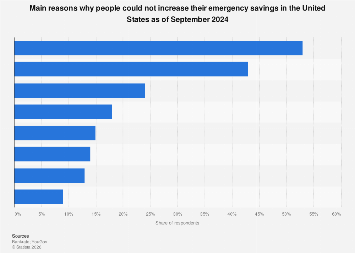

For years, the gold standard for automotive product development cycles among established global players typically spanned 48 to 60 months. Indian automakers have now achieved parity, or even surpassed, this traditional pace, with current development timelines often ranging between 36 and 40 months for new models. However, the ultimate benchmark remains the blistering pace set by Chinese OEMs, who are reportedly capable of rolling out entirely new products within 24 months, as highlighted in a November 2024 Boston Consulting Group update. This gap, though narrowing, underscores the ambitious trajectory of Indian manufacturers. Nalinikanth Gollagunta, CEO of Mahindra’s automotive division, articulated this relentless pursuit of agility on the sidelines of the XEV 9S launch in November, stating, "It used to be 5 years, with Inglo [Mahindra’s vehicle platform], we are now at 33 months or so, but the notion is, we have to keep collapsing that, there is no question." He emphasized the critical need for swift action, particularly in high-volume segments like sub-4-meter vehicles, where market trends shift rapidly.

This acceleration is a multi-faceted endeavor, underpinned by significant investments in digital tools, enhanced auto component manufacturing capacities, and the adoption of flexible, modular vehicle platforms. Advanced digital technologies, including sophisticated computer-aided design (CAD), engineering (CAE), and manufacturing (CAM) software, are now central to the design and prototyping phases. Virtual reality (VR) and augmented reality (AR) are increasingly being deployed to simulate designs and manufacturing processes, drastically reducing the need for physical prototypes and accelerating validation. Chandrasekhar Krishnamurthy, global director and head of product management at BorgWarner, a major US-based component supplier, observed that Indian automakers are indeed drawing inspiration from the Chinese model, yet they infuse it with their unique market requirements. "In India, we are seeing that they want to also go in the same direction where they would like to have the China speed, but we also see that there are more specific requirements Indian OEMs want," Krishnamurthy noted, adding that the ultimate speed of execution often hinges on the level of customization desired by the OEMs.

A critical element in this accelerated product roadmap is the deep integration and collaboration with the automotive supply chain. Indian OEMs are not just dictating specifications; they are actively pushing their component partners to benchmark against Chinese suppliers in terms of speed, cost-efficiency, and innovation. This has given rise to the concept of "Tier 0.5 suppliers" – a new class of partners who move beyond merely supplying parts (Tier II) or full systems (Tier I) to become integral participants in the early design and development phases. These suppliers proactively contribute to product conceptualization, shared intellectual property, and concurrent engineering, effectively becoming an extension of the OEM’s R&D arm. Companies like Samvardhana Motherson International Ltd, Tata AutoComp Systems Ltd, Lumax Auto Technologies, and Belrise Industries Ltd are actively pursuing this Tier 0.5 designation, recognizing the strategic imperative of such deep collaboration. Anmol Jain, managing director at Lumax Auto Technologies, confirmed this trend, stating that Indian OEMs are "way more agile and way more responsive and definitely faster than the Europeans or maybe some of the Japanese makers as well," and are actively encouraging suppliers to adopt Chinese-level development speeds.

The economic implications of this accelerated product development are far-reaching. India, already the world’s third-largest automotive market, benefits from enhanced domestic manufacturing capabilities, leading to job creation across the entire value chain—from R&D and engineering to manufacturing and sales. This strategic shift fosters a more robust and self-reliant automotive ecosystem, attracting further investment in advanced manufacturing processes and cutting-edge technologies. The ability to rapidly introduce new models, particularly in segments like SUVs and electric vehicles (EVs), allows Indian OEMs to capture evolving consumer preferences and stay ahead of the curve. This agility is crucial in a market where consumers increasingly demand advanced features, connectivity, and sustainable mobility solutions. The government’s Production Linked Incentive (PLI) schemes and FAME II subsidies for EVs further incentivize this localized innovation and rapid deployment.

While the domestic market remains a primary focus for homegrown players like Tata and Mahindra, with their sales predominantly concentrated within India, the long-term vision includes strengthening their global competitiveness. Maruti Suzuki India Ltd, for example, which is a unit of Japan’s Suzuki, demonstrates the potential for export excellence, with approximately one-fifth of its total sales coming from international markets, spanning over 100 countries. Rahul Bharti, Senior Executive Officer-Corporate Affairs at Maruti Suzuki, emphasized that exports serve as the ultimate "fire test" of product development excellence, validating a product’s appeal and regulatory compliance across diverse global markets. This aspirational benchmark highlights the next frontier for Tata and Mahindra as they refine their rapid development processes: building products that not only meet stringent domestic demands but also possess the inherent quality, durability, and regulatory compliance to succeed on the global stage.

The journey towards "China speed" is not without its challenges. Maintaining stringent quality control and ensuring robust safety standards under compressed timelines requires sophisticated testing protocols and an unyielding commitment to engineering excellence. Navigating the complex and often divergent regulatory landscapes of international markets adds another layer of complexity for future export ambitions. Furthermore, attracting and retaining top-tier talent in areas like software engineering, data analytics, and advanced materials science is critical for sustaining this pace of innovation. Despite these hurdles, the momentum is undeniable. Over the next five years, the top four carmakers in India—Maruti, Mahindra, Hyundai, and Tata Motors—are collectively slated to launch more than two dozen new products, encompassing facelifts, model upgrades, and entirely new nameplates. This flurry of activity underscores a vibrant and dynamic industry that is not merely catching up but actively shaping its own destiny through strategic agility and relentless innovation. The era of protracted development cycles is fading, replaced by a new paradigm where speed, responsiveness, and collaborative innovation are the hallmarks of success in the global automotive arena.