India, a pivotal player in the global pharmaceutical landscape often lauded as the "Pharmacy of the World," is embarking on a significant overhaul of its bulk drug licensing and regulatory framework. This ambitious initiative seeks to build a meticulously detailed database of active pharmaceutical ingredient (API) traders, dramatically enhance the traceability of imported raw materials, and establish clear lines of accountability within its sprawling $50-billion pharmaceutical market. The reforms come at a critical juncture, as the nation grapples with heightened international scrutiny following incidents involving substandard cough syrups linked to child deaths in Uzbekistan, Gambia, Cameroon, and within India itself, tarnishing its reputation.

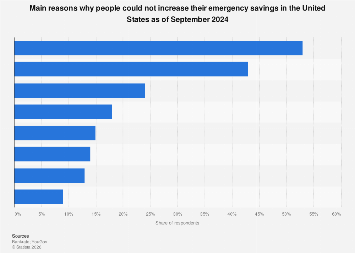

The proposed regulatory shift by the Drugs Controller General of India (DCGI) marks a decisive departure from the current generalized licensing system, which conflates raw material suppliers with finished medicine distributors. This archaic "umbrella approach" has long been identified as a critical vulnerability, impeding effective oversight. The new mechanism aims to rectify this by introducing a distinct licensing regime specifically for bulk drugs and advanced intermediates. This move is poised to equip regulators with a long-missing, granular registry of the estimated 1.2 million entities involved in the bulk drug trade, a segment valued at approximately $3.5 billion in the fiscal year 2025 alone.

The imperative for such a comprehensive reform is underscored by India’s substantial reliance on imported APIs. More than 70% of the raw materials crucial for drug manufacturing originate from China, a dependency that presents both economic and strategic vulnerabilities. This heavy reliance extends to critical substances such as Penicillin G and Amoxicillin for broad-spectrum antibiotics, Azithromycin for respiratory and skin infections, Rifampicin for tuberculosis treatment, Atorvastatin for cholesterol management, and Metformin, the primary raw material for Type-2 diabetes medication. The lack of precise data on these vast import flows and the myriad traders involved has created significant blind spots in the supply chain, making it challenging to identify and isolate sources of contamination or substandard inputs quickly.

Recent tragic incidents, particularly those involving diethylene glycol contamination in cough syrups, have brought the lack of transparency in the raw material supply chain into sharp focus. These events highlighted not only the profound safety concerns but also the urgent need to monitor the quality of high-risk solvents, including propylene glycol, which are integral to pharmaceutical formulations. Experts within the government emphasize that the current licensing parameters, which broadly apply to both bulk drug dealers and formulation sellers, are fundamentally inadequate. Bulk drug sellers manage complex chemical-based processes and supply manufacturers, whereas formulation sellers interact directly with retailers and the public. By segregating these licenses, regulators can impose more stringent storage, handling, and quality control conditions tailored to the specific risks associated with chemical ingredients. This proactive approach aims to ensure that in the event of a quality compromise, specific dealers responsible for distributing substandard materials can be immediately identified and held accountable.

The economic implications of this regulatory shift are substantial. India’s total pharmaceutical-related imports, encompassing both finished products and raw materials, reached approximately $8.2 billion in FY2024, with bulk drugs constituting a dominant share of this inflow. The nation’s API market is projected for robust growth, expected to reach $38.13 billion by 2034, expanding at a compound annual growth rate (CAGR) of 8.50% from 2025. This burgeoning market underscores the economic significance of a robust and transparent regulatory framework that not only safeguards public health but also fosters industry growth and investor confidence.

The proposed framework involves the introduction of a separate application form for bulk drug wholesale licenses, distinguishing it clearly from the existing common wholesale license used for both formulations and bulk drugs. This granular approach will allow the government to collect detailed data on the specific locations, chemicals traded, imported, manufactured, and supplied by each of the millions of companies operating in the sector. Currently, the absence of such specific data means regulators lack a clear picture of the true number of licenses exclusively for bulk drugs. This initiative is a crucial step towards mapping the entire value chain, addressing existing gaps, and enhancing supply chain intelligence, a challenge highlighted by industry leaders like Namit Joshi, Chairman of the Pharmaceutical Export Promotion Council of India (Pharmexcil) and Director of Centrient Pharmaceuticals. Joshi stresses that APIs and excipients are the foundational elements of medicine quality, and any compromise at this initial stage places immense stress on the quality of fixed-dose formulations. A robust and transparent regulatory framework is, therefore, indispensable for managing the API and excipient quality management system, whether for domestically produced or imported materials.

This regulatory tightening is not an isolated measure but part of a broader strategic effort by the Indian government to strengthen its pharmaceutical ecosystem. Complementary initiatives include the implementation of a Minimum Import Price (MIP) on certain bulk drugs, APIs, and intermediates—such as potassium clavulanate, Penicillin-G, and Amoxicillin—designed to bolster domestic manufacturing and mitigate the influx of cheaper imports, particularly from China. Furthermore, the government’s Production-Linked Incentive (PLI) scheme, launched in 2020 with a substantial financial outlay of ₹6,940 crore for FY2023 to FY2029, has been instrumental in encouraging domestic API manufacturing. Under this scheme, 48 projects have been selected, with 34 already commissioned for the production of 25 critical bulk drugs, marking a significant step towards reducing import dependence and fostering self-reliance.

Legal experts and industry associations have largely welcomed the impending changes. Akash Karmakar, a corporate and regulatory advisory partner at Panag & Babu law firm, notes that wholesale licenses are currently issued without adequate oversight mechanisms for the supply chains feeding manufacturers, as the focus has historically been on retail sales. He views the new licensing framework as a "welcome" and "important" development that addresses a critical gap in the regulatory regime, even potentially boosting the ease of doing business for compliant manufacturers and traders, including those dealing with Chinese APIs and excipients. R.K. Agrawal, former president of the Bulk Drugs Manufacturers Association of India (BDMAI), which represents a significant portion of India’s bulk drug companies, believes the government will finally gain a comprehensive understanding of all entities handling bulk drugs and APIs. He anticipates that this will lead to substantial improvements, particularly in combating issues like pilferage and spurious medicines in transit.

While a draft notification for this new mechanism is actively being developed, government officials acknowledge that its full implementation will be a complex process, given that it represents a completely new regulatory paradigm. The transition will require careful planning, stakeholder engagement, and potentially significant technological infrastructure to manage the vast new database. Nevertheless, the strategic intent is clear: to fortify India’s pharmaceutical supply chain, enhance the quality and safety of medicines, and ultimately reinforce the nation’s credibility as a reliable and responsible global pharmaceutical manufacturing hub, ensuring that its "Pharmacy of the World" moniker is synonymous with uncompromising quality and robust accountability.