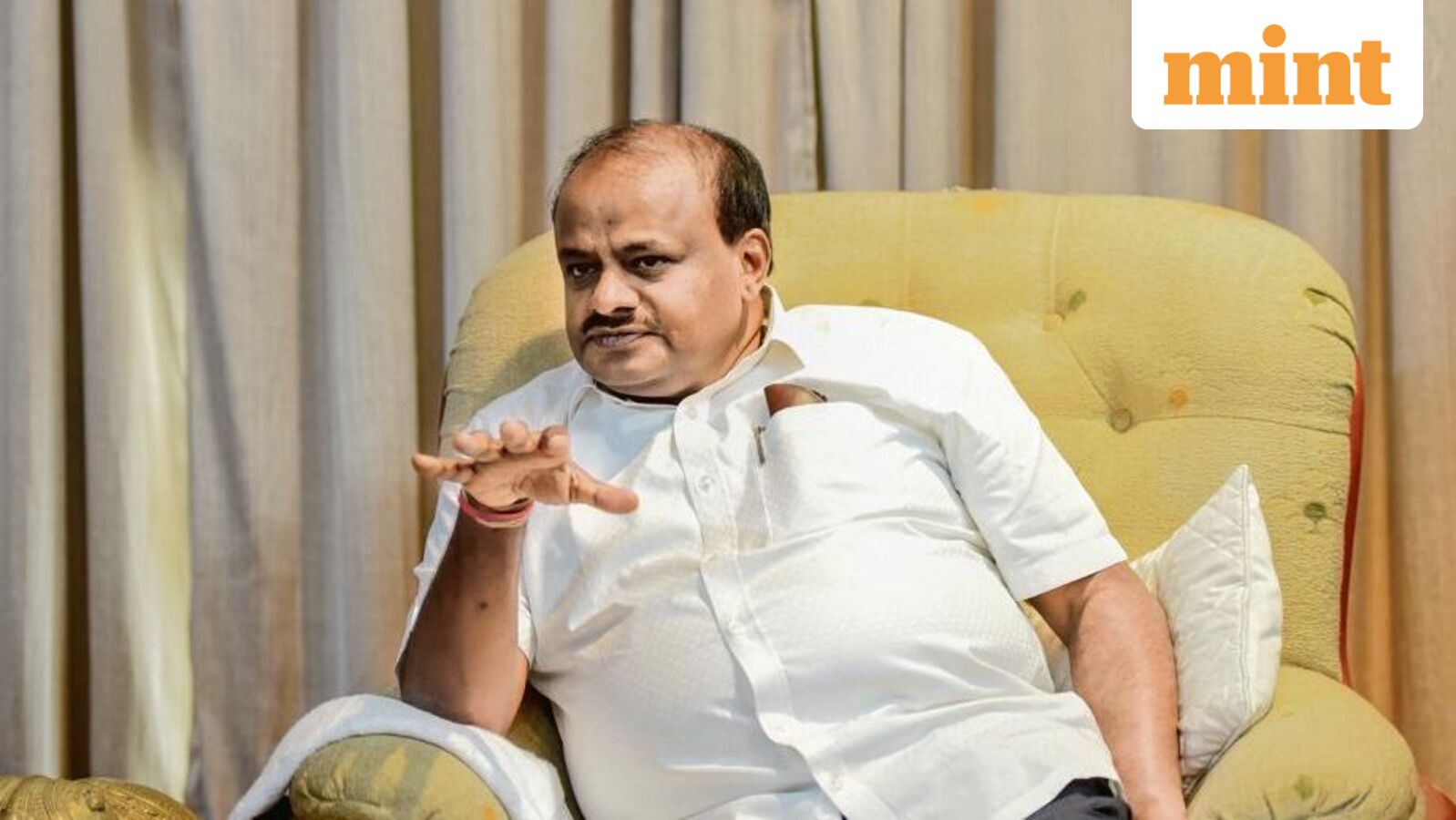

A pivotal stakeholder consultation, chaired by India’s Union Heavy Industries Minister H.D. Kumaraswamy, recently brought together over 20 industry leaders, underscoring the nation’s ambitious drive to establish a robust domestic supply chain for sintered rare earth magnets. This gathering signals a critical acceleration in New Delhi’s strategy to bolster self-reliance in a sector deemed indispensable for the burgeoning electric vehicle (EV) market, renewable energy infrastructure, and crucial defense applications. The meeting meticulously addressed industry concerns and refined the contours of the government’s ₹7,280-crore incentive scheme, designed to catalyze local manufacturing and mitigate global supply chain vulnerabilities.

At the heart of this initiative is a comprehensive incentive package targeting the establishment of 6,000 tonnes of rare earth magnet capacity over a seven-year period. The scheme, which received Union cabinet assent in late November, allocates ₹750 crore as capital incentives for setting up five new manufacturing plants. This upfront investment is complemented by sales-linked incentives, disbursed over five years following an initial two-year gestation period for plant commissioning. The strategic intent is clear: to cultivate a vibrant midstream industry capable of transforming refined rare earth oxides into high-performance magnets, thereby reducing India’s reliance on external sources for these critical components.

The geopolitical landscape of rare earth elements, often dubbed "the vitamins of modern industry," has made such a strategic push imperative. China currently dominates the global rare earth supply chain, controlling an estimated 60% of mining capacity and a staggering 90% of processing capabilities. This near-monopoly grants Beijing significant leverage, as demonstrated by its past actions, including export restrictions on specific rare earth magnets and technologies. Such moves have rattled global manufacturers and amplified the urgency for nations worldwide to diversify their sourcing and processing capabilities. India’s scheme is a direct response to this vulnerability, aiming to shield its vital industries from potential supply disruptions and price volatility.

The significance of rare earth magnets, particularly neodymium-praseodymium (NdPr) magnets, cannot be overstated. These powerful permanent magnets are fundamental to a wide array of high-tech applications. In the electric vehicle sector, they are crucial for manufacturing efficient and compact motors, driving the global transition away from fossil fuels. The renewable energy domain relies heavily on them for the permanent magnet generators used in modern wind turbines, enhancing their efficiency and power output. Beyond commercial applications, rare earth magnets are indispensable in advanced defense systems, including precision-guided munitions, radar systems, and sophisticated communication equipment, making domestic production a matter of national security. With India’s aggressive targets for EV adoption and renewable energy expansion, the demand for these magnets is projected to surge exponentially in the coming decade. Industry forecasts suggest the global rare earth magnet market, valued at over $20 billion in 2023, could exceed $35 billion by 2030, with a substantial portion of this growth driven by the burgeoning Asian markets.

A cornerstone of the government’s strategy to ensure raw material security for the nascent domestic industry is the role of state-run India Rare Earths Ltd (IREL). During the consultation, government officials assured stakeholders that IREL would provide 500 tonnes of NdPr oxide annually to selected beneficiaries under the scheme. NdPr oxide is a key precursor for the powerful magnets. This commitment from IREL, which possesses a current stockpile of approximately 500 tonnes of rare earth oxides, capable of supporting the production of around 1,500 tonnes of magnets based on a thumb rule of one unit of oxide yielding three units of magnets, offers a crucial initial supply buffer. Furthermore, the meeting saw participation from international rare earth oxide suppliers, who reportedly assured guaranteed supply, reinforcing confidence in the availability of critical inputs. This two-pronged approach – leveraging domestic reserves through IREL and securing international partnerships – is vital for de-risking the supply chain in the short to medium term.

The intricate process of rare earth magnet manufacturing typically involves three stages: upstream, midstream, and downstream. The upstream segment focuses on the mining and extraction of rare earth ores to produce oxides. The midstream process involves transforming these oxides into metals and subsequently into magnets, a technologically intensive step. Finally, the downstream stage involves fashioning these magnets for specific industrial applications. India’s historical strength has primarily been in the upstream segment, with IREL operating as the nation’s sole rare earth oxide producer. However, the current scheme is specifically designed to bridge the critical midstream gap, fostering a robust domestic capacity to convert oxides into high-value magnets. This strategic intervention aims not just at self-sufficiency but also positions India to become a significant player in the global rare earth value chain.

The economic implications of this initiative are far-reaching. By localizing rare earth magnet production, India stands to create thousands of direct and indirect jobs, stimulate technological innovation, and attract significant domestic and foreign investment into the manufacturing sector. It will also lead to substantial foreign exchange savings by reducing reliance on imported magnets. Beyond the direct economic benefits, the scheme aligns perfectly with India’s broader ‘Make in India’ and ‘Atmanirbhar Bharat’ (self-reliant India) campaigns, fostering an ecosystem of advanced manufacturing and enhancing the nation’s strategic autonomy in critical technologies. Analysts project that a successful implementation could see India capture a significant share of the global non-Chinese rare earth magnet market, estimated to be worth several billion dollars annually.

However, the path to rare earth magnet independence is not without its challenges. Developing advanced processing technologies, establishing environmentally sustainable mining and refining practices, and attracting specialized talent are crucial hurdles. Rare earth processing is often energy-intensive and can generate significant environmental byproducts, necessitating stringent regulatory oversight and investment in green technologies. Moreover, competing with established global players requires consistent innovation, quality control, and competitive pricing. Yet, India’s large domestic market, combined with governmental backing and a growing pool of skilled engineers, provides a strong foundation. The engagement with global suppliers also indicates a pragmatic approach to securing technology transfer and expertise.

Looking ahead, India’s strategic foray into rare earth magnet manufacturing represents a calculated and critical step towards securing its economic future and technological sovereignty. By fostering domestic production, diversifying raw material sourcing, and investing in midstream processing, New Delhi is not merely addressing a supply chain vulnerability but is actively shaping its role in the global high-tech economy. The successful implementation of this ₹7,280-crore scheme could transform India from a dependent consumer into a self-reliant producer and, potentially, a significant exporter of these indispensable components, thereby recalibrating the global rare earth power balance.